Ymaguchi Electric Ind. Co., Ltd.

Yamaguchi Electric Industry Co., Ltd.

Global approach to the development

Top Page > YEC Features

YEC Features

Tests are conducted under heat, water and vibration conditions

A vital aspect of automotive part quality is the ability to withstand the vibrations, sand, dust, and heat of the vehicle’s operating environment. In the process of joint development with various automakers, YEC products undergo a wide variety of evaluation tests. They are similarly tested again during production, guaranteeing maximum quality.

Examples of evaluation tests

- Endurance test (hundreds of hours of continual or cycling operation)

- High/low temperature test

- Temperature and humidity cycle test

- Thermal shock test

- Water spray test

- Salt spray test

- High-temperature, high-pressure washing test

- Vibration test

- Dust test

- Static electricity test

- High Voltage spike resistance test

- Electrical interference test (EMI, RFI, EMC).

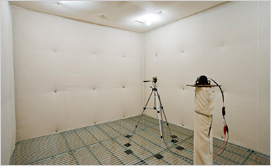

- Sound pressure measurement

- Sound Directionality test

Rigorous tests are conducted, including water and heat resistance tests

An anechoic chamber used for high-precision acoustic tests

YEC products meet diverse and rigorous quality assurance standards worldwide

YEC products are supplied to customers not only in Japan but throughout the world, and meet global quality standards. In addition to SAE, the global standard for backup alarms, our products comply scrupulously with UL safety standards for flame retardancy and other international standards. Having passed through our intensive quality control system, products for our domestic customers also meet automakers’ exacting internal standards.

|

|

|

|

|

|